References

The projects mentioned here are an excerpt from our current project portfolio.

We would be pleased to send you a detailed reference list upon request.

Radiation protection building - Mühldorf am Inn

The world’s first radiation protection building using the Forster Sandwich Construction® method is located in Mühldorf am Inn.

Radiation protection building - Mühldorf am Inn

Client: Mühleninsel Radiology Clinic

Location: Mühldorf am Inn, Germany

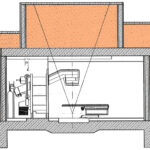

Number of radiation protection rooms: 1

Description: The world’s first radiation protection building using the Forster Sandwich Construction® method is located in Mühldorf am Inn. Despite the most unfavourable weather conditions with temperatures as low as 14°F and large amounts of snow, the shell construction was finished in just 3 months. A mineral bulk filling of gypsum gravel was used in this pilot facility. Parameters such as compression values, filling pressures etc. were measured and monitored during construction in order to gain more insight into radiation protection building construction.

Equipment: Elekta Precise Treatment System 15 MeV

Radiation protection building - Fürth

The Fraunhofer Institute for integrated circuits (IIS) needed a new testing facility with specific characteristics for developing new XXL computer tomography systems.

Radiation protection building - Fürth

Client: Fraunhofer Gesellschaft

Location: Fürth – Atzenhof

Number of radiation protection rooms: 1

Description: The Fraunhofer Institute for integrated circuits (IIS) needed a new testing facility with specific characteristics for developing new XXL computer tomography systems. The turkey radiation protection building with an area of 24 x 24 m and a height of 15 m was constructed in just 5 months.

Equipment: Siemens Silac® 9 MeV for XXL-CT

Radiation protection building - Wiener Neustadt

MedAustron required a radiation protection facility of 136 m length with 4 treatment / testing rooms for their particle accelerator.

Radiation protection building - Wiener Neustadt

Client: EBG MedAustron GmbH

Location: Wiener Neustadt, Österreich

Number of radiation protection rooms: 4 + 1Beschleunigerraum

Description: MedAustron required a radiation protection facility of 136 m length with 4 treatment / testing rooms for their particle accelerator. The accelerator is used for both cancer treatment and basic research. Replacement of the massive concrete construction method that was initially planned with a sustainable Forster Sandwich Construction® enabled lowering construction costs to an extent that put the project back on track with a realistic budget. The decision against the massive concrete construction in favour of a bulk filling saved 25000 m3 of cast in-situ concrete. Gravel from the excavated construction pit was used as bulk filling, saving approx. 10000 truck runs through the town center and of course massive amounts of concrete. Should deconstruction be required in the future, the thin concrete structures can be disassembled using conventional construction equipment and the gravel can be recovered without any contaminations. It is a “green building” from construction to deconstruction.

Equipment: Teilchenbeschleuniger Protonen: 800 MeV; Kohlenstoffionen: 400 MeV/u

Mobile radiation protection building - Feldkirchen

If a temporary radiation protection room is required inside an existing hall, Forster Sandwich Construction® offers a cost-effective solution.

Mobiler Strahlenschutzraum - Feldkirchen

Client: BrainLAB AG Feldkirchen

Location: Feldkirchen bei München

Description: If a temporary radiation protection room is required inside an existing hall, Forster Sandwich Construction® offers a cost-effective solution. The task was to equip a hall with a clear internal height of approx. 7.0 m with a radiation protection room of approx. 6.5 m height without altering the existing floor slab. The inner and outer shells were bolted to a number of prefabricated base elements. The space between the shells was then filled in layers before being compacted. In case of deconstruction, the radiation protection room can easily be disassembled and its materials can be separated and recycled or reused in a different construction. The location-independent construction method enables owners to benefit from shorter depreciation periods than in fixed installations.

Radiation protection building for TomoTherapy® Hi•Art - Bamberg

A new radiation protection building was constructed next to an existing radiation protection room to accommodate the new Hi•Art irradiation system.

Strahlenschutzraum for TomoTherapy® Hi•Art - Bamberg

Client: Sozialstiftung Bamberg

Location: Bamberg

Number of radiation protection rooms: 1

Description: For the new installation of the Hi•Art irradiation system, a new radiation protection structure was built next to an existing radiation protection room. In order to enable the construction work to be carried out during ongoing operations, the adjoining room had to be adapted to the new requirements within a weekend.

Equipment: TomoTherapy® Hi•Art System 6 MeV

Toughening up a Radiation protection building - Bamberg

A new radiation protection building was constructed next to an existing radiation protection room to accommodate the new Hi•Art irradiation system.

Toughening up a Radiation protection building - Bamberg

Client: Sozialstiftung Bamberg

Location: Bamberg

Number of radiation protection rooms: 1

Description: For the new installation of the Hi•Art irradiation system, a new radiation protection structure was built next to an existing radiation protection room. In order to enable the construction work to be carried out during ongoing operations, the adjoining room had to be adapted to the new requirements within a weekend. For this purpose, the existing room was uncovered and provided with a facing shell. The space created in this way was filled in layers with a bulk mineral filling and compacted. The use of Forster Sandwich Construction® and the associated high degree of prefabrication made it possible to realize the project within this short time window.

Equipment: Elekta Synergy 15 MeV

System-Lining - Rödermark Urberach

For the new construction of a supermarket in Rödermark Urberach, Germany, construction of a hillside retaining wall was required alongside a railway line.

Hillside retaining wall in Rödermark-Urberach

For the new construction of a supermarket in Rödermark Urberach, Germany, construction of a hillside retaining wall was required alongside a railway line. Railway operations could not be interrupted for this project. The retaining wall built with the Forster System Lining method has a length of 230 m and covers a height difference of 4 m. During construction as well as after completion, the inspectors of the railway network operator did not identify any settlements in the track area.

System-Lining - For an apartment building

A common problem in constructing underground parking is neighbours not giving permission for underpinning works on their property, which are required for erecting basement walls along property lines.

Construction of an apartment building abutting property lines

A common problem in constructing underground parking is neighbours not giving permission for underpinning works on their property, which are required for erecting basement walls along property lines. Forster System Lining enables lowering the actual outer wall right at the property line. The use of sheet pilings or bored pile walls is not required.

System-Building - Ingolstadt

A school pavilion was constructed as a Forster System Building at the south-western school complex in Ingolstadt as a sustainable alternative to a container building.

Pavilion at the south-western school complex in Ingolstadt

A school pavilion was constructed as a Forster System Building at the south-western school complex in Ingolstadt as a sustainable alternative to a container building.

The two-storey building has a length of 43.6 m and a width of 19 m on a ground area of 823 m2. It was designed for up to 360 students and has 12 classrooms along with the required ancillary rooms.

Radiation protection building - Mühldorf am Inn

The world’s first radiation protection building using the Forster Sandwich Construction® method is located in Mühldorf am Inn.

Radiation protection building - Mühldorf am Inn

Client: Mühleninsel Radiology Clinic

Location: Mühldorf am Inn, Germany

Number of radiation protection rooms: 1

Description: The world’s first radiation protection building using the Forster Sandwich Construction® method is located in Mühldorf am Inn. Despite the most unfavourable weather conditions with temperatures as low as 14°F and large amounts of snow, the shell construction was finished in just 3 months. A mineral bulk filling of gypsum gravel was used in this pilot facility. Parameters such as compression values, filling pressures etc. were measured and monitored during construction in order to gain more insight into radiation protection building construction.

Equipment: Elekta Precise Treatment System 15 MeV

Radiation protection building - Fürth

The Fraunhofer Institute for integrated circuits (IIS) needed a new testing facility with specific characteristics for developing new XXL computer tomography systems.

Radiation protection building - Fürth

Client: Fraunhofer Gesellschaft

Location: Fürth – Atzenhof

Number of radiation protection rooms: 1

Description: The Fraunhofer Institute for integrated circuits (IIS) needed a new testing facility with specific characteristics for developing new XXL computer tomography systems. The turkey radiation protection building with an area of 24 x 24 m and a height of 15 m was constructed in just 5 months.

Equipment: Siemens Silac® 9 MeV for XXL-CT

Radiation protection building - Wiener Neustadt

MedAustron required a radiation protection facility of 136 m length with 4 treatment / testing rooms for their particle accelerator.

Radiation protection building - Wiener Neustadt

Client: EBG MedAustron GmbH

Location: Wiener Neustadt, Österreich

Number of radiation protection rooms: 4 + 1Beschleunigerraum

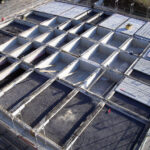

Description: MedAustron required a radiation protection facility of 136 m length with 4 treatment / testing rooms for their particle accelerator. The accelerator is used for both cancer treatment and basic research. Replacement of the massive concrete construction method that was initially planned with a sustainable Forster Sandwich Construction® enabled lowering construction costs to an extent that put the project back on track with a realistic budget. The decision against the massive concrete construction in favour of a bulk filling saved 25000 m3 of cast in-situ concrete. Gravel from the excavated construction pit was used as bulk filling, saving approx. 10000 truck runs through the town center and of course massive amounts of concrete. Should deconstruction be required in the future, the thin concrete structures can be disassembled using conventional construction equipment and the gravel can be recovered without any contaminations. It is a “green building” from construction to deconstruction.

Equipment: Teilchenbeschleuniger Protonen: 800 MeV; Kohlenstoffionen: 400 MeV/u

Mobile radiation protection building - Feldkirchen

If a temporary radiation protection room is required inside an existing hall, Forster Sandwich Construction® offers a cost-effective solution.

Mobiler Strahlenschutzraum - Feldkirchen

Client: BrainLAB AG Feldkirchen

Location: Feldkirchen bei München

Description: If a temporary radiation protection room is required inside an existing hall, Forster Sandwich Construction® offers a cost-effective solution. The task was to equip a hall with a clear internal height of approx. 7.0 m with a radiation protection room of approx. 6.5 m height without altering the existing floor slab. The inner and outer shells were bolted to a number of prefabricated base elements. The space between the shells was then filled in layers before being compacted. In case of deconstruction, the radiation protection room can easily be disassembled and its materials can be separated and recycled or reused in a different construction. The location-independent construction method enables owners to benefit from shorter depreciation periods than in fixed installations.

Radiation protection building for TomoTherapy® Hi•Art - Bamberg

A new radiation protection building was constructed next to an existing radiation protection room to accommodate the new Hi•Art irradiation system.

Strahlenschutzraum for TomoTherapy® Hi•Art - Bamberg

Client: Sozialstiftung Bamberg

Location: Bamberg

Number of radiation protection rooms: 1

Description: For the new installation of the Hi•Art irradiation system, a new radiation protection structure was built next to an existing radiation protection room. In order to enable the construction work to be carried out during ongoing operations, the adjoining room had to be adapted to the new requirements within a weekend.

Equipment: TomoTherapy® Hi•Art System 6 MeV

Toughening up a Radiation protection building - Bamberg

A new radiation protection building was constructed next to an existing radiation protection room to accommodate the new Hi•Art irradiation system.

Toughening up a Radiation protection building - Bamberg

Client: Sozialstiftung Bamberg

Location: Bamberg

Number of radiation protection rooms: 1

Description: For the new installation of the Hi•Art irradiation system, a new radiation protection structure was built next to an existing radiation protection room. In order to enable the construction work to be carried out during ongoing operations, the adjoining room had to be adapted to the new requirements within a weekend. For this purpose, the existing room was uncovered and provided with a facing shell. The space created in this way was filled in layers with a bulk mineral filling and compacted. The use of Forster Sandwich Construction® and the associated high degree of prefabrication made it possible to realize the project within this short time window.

Equipment: Elekta Synergy 15 MeV

System-Lining - Rödermark Urberach

For the new construction of a supermarket in Rödermark Urberach, Germany, construction of a hillside retaining wall was required alongside a railway line.

Hillside retaining wall in Rödermark-Urberach

For the new construction of a supermarket in Rödermark Urberach, Germany, construction of a hillside retaining wall was required alongside a railway line. Railway operations could not be interrupted for this project. The retaining wall built with the Forster System Lining method has a length of 230 m and covers a height difference of 4 m. During construction as well as after completion, the inspectors of the railway network operator did not identify any settlements in the track area.

System-Lining - For an apartment building

A common problem in constructing underground parking is neighbours not giving permission for underpinning works on their property, which are required for erecting basement walls along property lines.

Construction of an apartment building abutting property lines

A common problem in constructing underground parking is neighbours not giving permission for underpinning works on their property, which are required for erecting basement walls along property lines. Forster System Lining enables lowering the actual outer wall right at the property line. The use of sheet pilings or bored pile walls is not required.